A&P Fabricating Solutions is now hiring custom metal fabricators and experience tig welders! Please send resumes to adamk@apfabsolutions.com

A&P Fabricating Solutions is now hiring custom metal fabricators and experience tig welders! Please send resumes to adamk@apfabsolutions.com

Diverse Equipment Capabilities

A & P Fabricating Solutions, LLC has the equipment capabilities you need to complete your project on time and on budget. Count on us for all your custom fabrication needs.

We provide machining & fabrication services for the following industries & categories: Food Processing, Pharmaceutical, Packaging, Emission Control, Heat Recovery, Heat Collection, Guarding, Catwalks, Railings, and Ducting Packages.

Laser

Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the material or the laser beam generated. A typical commercial laser for cutting materials involved a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas.

Plate rolling

Our plate rolling machine rolls different kinds of metal sheets into a round or conical shape. It’s also sometimes called a “roll bending machine”, “plate bending machine”, or simply “rolling machine”.

Press break

Bending is the manufacturing process that produces a v-shape, u-shape, or channel shape along a straight axis in ductile materials. Sheet metal is most commonly used. Equipment used includes box and pan brakes, brake presses, and other specialized machine presses. Typical products created by this process include boxes for electrical enclosures and rectangular ductwork.

Plasma

Plasma cutting is used to cut steel and other metals or materials of different thicknesses using a plasma torch. For this process, a gas such as oxygen, air, or an inert gas is blown from a nozzle at high speed. Other gases may be used, depending on the material being cut.

At the same time, an electrical arc is formed through the gas from the nozzle to the surface being cut, which turns some of that gas to plasma. The plasma is hot enough to melt the material being cut and moves quickly enough to blow molten metal away from the cut.

Plate Cutting

Lifting

Plate Shearing

Fabrication Capabilities

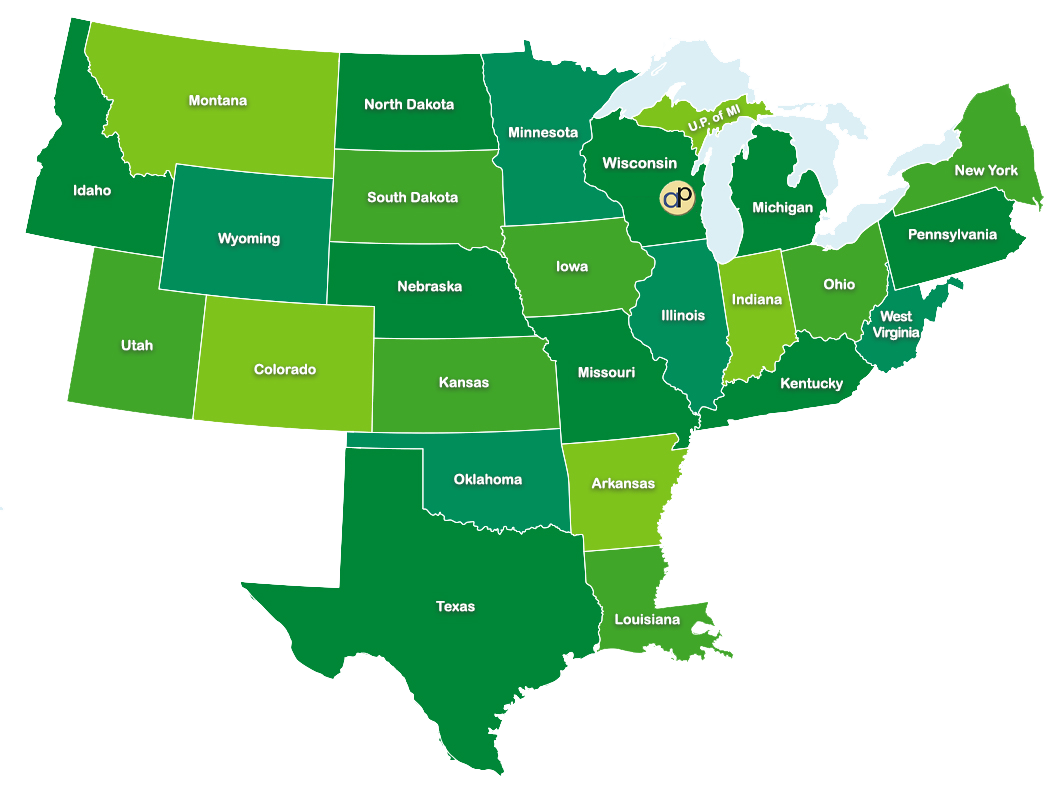

Headquartered in Appleton, Wisconsin we are the certified professionals to tackle your custom fabrication needs. A & P Fabricating Solutions, LLC has over 90 years of experience and you can depend on us for exceptional custom fabrication services. Serving the Mid-West of America.

A & P Fabricating Solutions, LLC

5007 Wren Drive

Appleton, WI 54913

Hours

Monday – Friday:

6:00 AM – 3:30 PM

A & P Fabricating Solutions, LLC

5007 Wren Drive

Appleton, WI 54913

Hours

Monday – Friday:

6:00 AM – 3:30 PM